Insulated Render

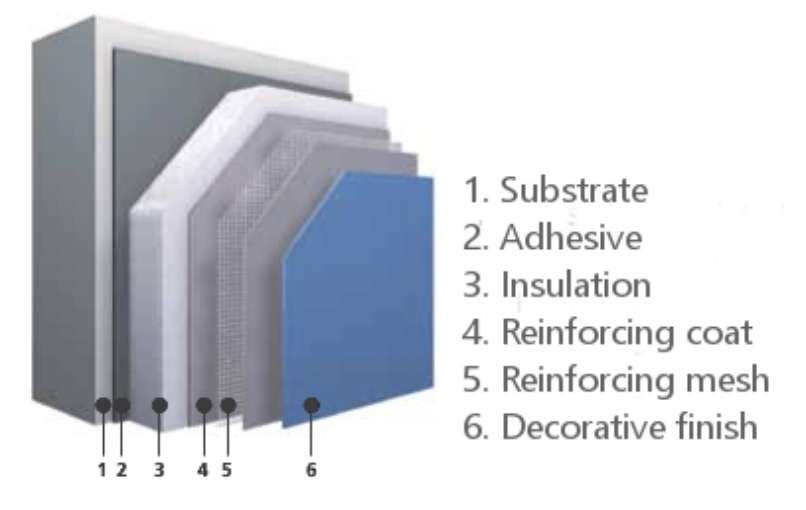

An insulated render system is a multi-layered approach to thermal insulation applied to the exterior of a building. These systems help improve thermal efficiency and enhance energy performance while protecting the building façade. It typically involves the following layers:

- Rigid Insulation: This layer consists of boards or sheets that provide thermal insulation.

- Reinforcing Mesh: Applied over the insulation, this mesh enhances structural integrity.

- Render Base Coat: A layer of base coat material is applied to the mesh.

- Finishing Coat: The final layer is a protective render finish.

Insulated render systems are commonly used for improving thermal efficiency and enhancing energy performance in buildings.

- Insulation: The core component of an insulated render system is the insulation material. Common options include:

- Expanded Polystyrene (EPS): Lightweight and easy to install, EPS slabs are mechanically fixed to the existing wall.

- Mineral Wool Slab: Provides good thermal performance and fire resistance.

- Phenolic Foam Slab: Offers excellent insulation properties.

- Mechanical Fixings: These are used to attach the insulation boards to the wall. They can be made of metal or plastic. To minimize thermal bridging, adhesive-fixed insulation or a track & rail system can be used.

- Mesh Reinforcement: A mesh is applied over the insulation to create a key backing for subsequent layers.

- Render Base Coat: This layer provides a smooth surface for the final finish. It’s typically applied over the mesh.

- Finish Coat: The outermost layer is the decorative render finish.

- Silicone Render: Durable and water-repellent.

- Mineral Render: Breathable and natural-looking.

- Polymer Plain Render: Versatile and available in various colors.

- Polymer Dashing Render: Textured finish with added aggregates.

- Rendabrick: Simulates brickwork appearance.

- Acrylic and Silicate Renders: Different finishes for aesthetic variety.

- EPS (Expanded Polystyrene) System:

- Prepare the Surface: Clean and repair the existing wall surface.

- Fix Insulation Boards: Mechanically fix EPS insulation boards to the wall using appropriate fixings (screws or nails).

- Apply Base Coat: Apply a base coat (usually cement-based) over the insulation boards.

- Install Reinforcement Mesh: Embed a fibreglass mesh into the base coat while it’s still wet.

- Apply Finish Coat: Once the base coat is dry, apply the final decorative render finish (e.g., silicone render, acrylic render).

- Mineral Wool System:

- Surface Preparation: Clean and repair the wall.

- Attach Insulation Slabs: Fix mineral wool slabs to the wall using adhesive or mechanical fixings.

- Base Coat Application: Apply a base coat (cementitious or polymer-based) over the insulation.

- Mesh Reinforcement: Embed a mesh into the base coat.

- Final Render Coat: Apply the chosen render finish (e.g., mineral render, acrylic render).

- Phenolic Foam System:

- Surface Preparation: As with other systems, prepare the wall.

- Fix Phenolic Foam Slabs: Attach phenolic foam slabs using mechanical fixings.

- Base Coat and Mesh: Apply a base coat and embed reinforcement mesh.

- Finish Coat: Apply the desired render finish.

The finish coat in an insulated render system is the outermost layer that provides both aesthetic appeal and protection.

- Types of Finish Coats:

- Silicone Render: Durable, water-repellent, and available in various colors.

- Mineral Render: Breathable and natural-looking.

- Acrylic Render: Versatile and easy to apply.

- Polymer Plain Render: Offers different finishes for aesthetic variety.

- Polymer Dashing Render: Textured finish with added aggregates.

- Rendabrick: Simulates brickwork appearance.

- Application Process:

- After applying the base coat (which provides a smooth surface), the finish coat is applied.

- It can be trowel-applied or sprayed onto the surface.

- The thickness of the finish coat varies based on the system and manufacturer’s recommendations.

- Benefits:

- Weather Resistance: Finish coats protect against rain, UV exposure, and temperature fluctuations.

- Decorative: They enhance the appearance of the building.

- Breathability: Some finishes allow moisture vapour to escape while maintaining water resistance.

CHOOSE MANUFACTURERS

Brand: Knauf

Model and Size: 1200x900mm - 1.08m2

Delivery Time: In stock, 1-2 days

12.5mm Knauf Aquapanel Exterior Cement Board. A provides a solid, dry base that can withstand the extreme weathering effects of wind, rain and snow. An ideal substrate for directly applied render finishes and can be used for exterior walls in ventilated systems as well as exterior ceilings and soffi..

£28.64

£34.37 inc VAT

Brand: Austrotherm

Model and Size: 600mm x 1250mm - 0.75m2

Delivery Time: 1 - 2 days

20mm XPS 300 Insulation Board - Square Edge - TOP-F 30 SF is an extruded polystyrene thermal insulation board designed for domestic, commercial, and industrial applications where high resistance to compression and water absorption is essential. The TOP-F 30 SF extruded polystyrene boards (XPS) are m..

£3.65

£4.38 inc VAT

Brand: Kubala

Model and Size: 60mm

Delivery Time: 1 - 2 days

Kubala Stucco Trowel, 60mm Stainless Steel Blade with a Welded-on Soft Handle is a specialised tool used in stucco application. The softer grip handle provides comfort during extended use. 60mm stucco trowel is considered relatively narrow and highly suitable for finishing work and achieving smoothe..

£7.50

£9.00 inc VAT

Brand: Arbet

Model and Size: 1000x500mm - 30m2

Delivery Time: In stock, 1-2 days

Arbet 10mm White Polystyrene Board is a lightweight, durable, and provides excellent thermal insulation properties. The polystyrene sheets can be used for insulating exterior walls, roofs, floors, and HVAC systems, offering effective thermal protection for buildings.CHARACTERISTICSLightweight and du..

£36.95

£44.34 inc VAT

Brand: Ceresit

Model and Size: CT137

Delivery Time: 5 - 7 days

Ceresit CT137 Mineral Render is used for making thin layer plasters on concrete substrates, traditional plasters, gypsum substrates and gypsum cardboards, gypsum fi bre boards, etc.We recommend the application of the plaster CT137 as façade plaster within Ceresit Ceretherm ETICS (External Thermal In..

£28.50

£34.20 inc VAT

Brand: Ceresit

Model and Size: 10 litres

Delivery Time: In stock, 1-2 days

Ceresit CT16 is designed for priming substrates before the application of renders, finishes and paint coats. It facilitates the application and texturing of plasters, optimizes the drying process and improves the plaster-to-substrate adhesion. Provides a uniform substrate, prevents stain build-up on..

£41.25

£49.50 inc VAT

Brand: Ceresit

Model and Size: 5 kg

Delivery Time: In stock, 1-2 days

Ceresit CT16 is designed for priming substrates before the application of renders, finishes and paint coats. It facilitates the application and texturing of plasters, optimizes the drying process and improves the plaster-to-substrate adhesion. Provides a uniform substrate, prevents stain build-up on..

£19.50

£23.40 inc VAT

Brand: Ceresit

Model and Size: CT174 - 1.0mm

Delivery Time: 5 - 7 days More options available

CharacteristicsDesigned for machine application,

Optimised consumption,

Uniform final structure,

Vapour permeable,

Low absorbability,

Resistant to damage and weather conditions,

UV resistant

Available in full palette of Ceresit Colours

ready to use

ApplicationExternal WallsOn cement render..

Brand: Ceresit

Model and Size: Ceresit CT177

Delivery Time: 3 - 5 days

CharacteristicsManufactured in several dozen colour arrangements,

Ready to use,

Resistant to weather conditions,

Resistant to abrasion,

Easy to keep clean

ApplicationsExternal walls,

Internal wallsCertificationsCeresit VWS Classic system: ETA-06/0260,

European Certificate of Conformity No.130..

Brand: Ceresit

Model and Size: CT240

Delivery Time: 2 - 4 days

Ceresit CT240 is an additive for thin-coat acrylic plasters like CT60, CT63, CT64, silicone-silicate plasters like CT174, CT175, silicone plasters like CT74, CT75, priming paints like CT15, CT16 acrylic paints like CT42, CT44, and silicone paints like CT48 and CT49. It accelerates binding and drying..

£12.00

£14.40 inc VAT

Brand: Ceresit

Model and Size: CT280

Delivery Time: 2 - 4 days

Ceresit CT280 Winter Additive is intended for use as an additive in the late autumn and early spring periods, when the temperature at night drops below zero so work can continue. It is used as an additive for Ceresit cementbase mineral adhesive mortars and adhesive and reinforcing mortars (CT83, CT8..

£10.50

£12.60 inc VAT

Brand: Ceresit

Model and Size: CT29 25Kg

Delivery Time: 5 - 7 days

CharacteristicsVapour permeable (breathable),

Resistant to weather conditions,

Good adhesion,

Reinforced with micro-fibres,

Easy to apply

ApplicationPour the contents of the package into a measured clean amount of cool water and mix until a homogeneous mass is obtained.

It is most convenient t..

£31.19

£37.43 inc VAT

Brand: Ceresit

Model and Size: 1.1m x 50m - 55m2

Delivery Time: In stock, 1-2 days

CharacteristicsAlkali-resistant,

Slip proof,

Tear proof

ApplicationThe ready prepared mortar should be spread evenly over the surface of the boards with a tooth trowel with 10-12 mm teeth. In the case of mineral wool boards prior to distribution must also be primed with mortar. In the prepared la..

£67.00

£80.40 inc VAT

Brand: Ceresit

Model and Size: CT327

Delivery Time: 2 - 3 Days

CharacteristicsAlkali-resistant,

Slip proof,

Tear proof,

High impact resistance.

ApplicationEmbed the glass-fibre mesh vertically into the fresh reinforcing mortar, with overlaps of approx. 10 cm in joint areas, then level the surface.Embed the webbing into the upper third of the reinforcing la..

Brand: Ceresit

Model and Size: CT34 - 25kg

Delivery Time: 7 - 10 days

Ceresit CT34 White Smooth Mineral Render is used to make smooth surfaces on reinforced layers in complex Ceresit Ceretherm thermal insulation systems. The material can also be used to repair traditional cement-lime plasters inside and outside buildings. Even thin-layer walls and ceilings can be made..

£41.80

£50.16 inc VAT

Brand: Ceresit

Model and Size: CT42 Acrylic Paint

Delivery Time: 1 - 2 days More options available

PropertiesLow absorbance

Damage resistant

Resistant to weather conditions

BioProtect formula – resistant

To the development of fungus, algae and mould

Available in full palette of Ceresit coloursApplicationsProtecting façadesProtecting concrete constructionsProtecting interiorsApplied on the mi..

£69.50

£83.40 inc VAT

Brand: Ceresit

Model and Size: CT49 Silix XD

Delivery Time: 2 - 3 Days More options available

PropertiesLow absorbance

High vapour permeability

Self-cleaningResistant to dirtHigh durability thanks to the Silix XD® formula

Crack-bridging

Highly resistant to weather conditions and UVTicsotropic

For use in areas open for biological contamination (fungi, algae, etc.)

Available in full pale..

Brand: Ceresit

Model and Size: CT54 Silicate Paint

Delivery Time: 1 - 2 days

PropertiesHigh vapour permeableHigh resistant to damage and cleaningWeather conditions resistantStability of colourBioProtect formula – resistant to the development of fungus, algae and mouldAvailable in full palette of Ceresit Colours of Nature®Ceresit CT 54 is used for painting façades and interio..

£80.00

£96.00 inc VAT

Brand: Ceresit

Model and Size: CT60 - 25kg 0.5mm

Delivery Time: 2 - 3 Days More options available

Ceresit CT60 is used for making thin-layer renders in External Wall Insulation Systems, on concrete substrates, on traditional renders, gypsum substrates and chipboards, gypsum cardboards, etc. It is recommended use CT60 as facade render within Ceresit ETICS (External Thermal Insulation Composite Sy..

£89.00

£106.80 inc VAT

Brand: Ceresit

Model and Size: CT60 - 25kg

Delivery Time: 1 - 2 days More options available

Ceresit CT60 White Acrylic Render is used for making thin-layer plasters on concrete substrates, traditional plasters, gypsum substrates and chipboards, gypsum cardboards, etc. The recommended application of CT60 is as façade plaster within complex system of warming walls of outside buildings Ceresi..

£54.12

£64.94 inc VAT

Brand: Ceresit

Model and Size: CT72 1.5mm

Delivery Time: 5 - 7 days More options available

PropertiesHighly vapour permeable and durableResistant to damage and cleaning

Resistant to weather conditions

BioProtect formula – resistant to the development of fungus, algae and mould

Possibility of the machine applicationRange of Ceresit coloursApplicationConcrete substratesTraditional plaste..

Brand: Ceresit

Model and Size: CT74 - 25kg

Delivery Time: 1 - 2 days More options available

Ceresit CT74 Silicone Render is used for making thin-layer plasters on concrete substrates, traditional plasters, gypsum substrates and chipboards, gypsum cardboards, etc. The recommended application of the plaster CT74 is as façade plaster within Ceresit ETICS (External Thermal Insulation Composite..

£69.30

£83.16 inc VAT

Brand: Ceresit

Model and Size: CT76 Solar Protect 1.5mm

Delivery Time: 1 - 2 days More options available

Notice: Please get in contact to select colourPropertiesHighly resistant to UVKeeps colourSelf-cleaning Resistant to dirtElastic and impact resistant

Very low absorption High vapour permeability

Resistant to most weather conditions

Comes in Ceresit range of coloursExtended shelf life..

£98.45

£118.14 inc VAT

Brand: Ceresit

Model and Size: CT77 1.2mm - 1.8mm

Delivery Time: 5 - 7 days More options available

PropertiesUV and abrasion resistance

Milky effect resistance

Easy to spread smoothWeather resistantResistant to dirtEasy to keep clean

Available in Ceresit ColoursApplicationsTraditional plastersConcrete substratesGypsum substrates and chipboardsGypsum cardboardsOutside on areas that can easily g..

Brand: Ceresit

Model and Size: CT79 1.5mm

Delivery Time: 5 - 7 days More options available

PorpertiesHighly elastic, reinforced with carbon, glass and polyacrylamid fibres combination

Extremely resistant to weather conditions

Extremely resistant to operating damages – Over 100 Joules forceExtremely resistant for thermal stressesReady to useSelf-cleaningHighly dirt resistantVery low wate..

Brand: Ceresit

Model and Size: CT84

Delivery Time: In stock, 1-2 days

Ceresit CT84 Express is used for fixing expanded polystyrene boards in the complex Ceresit Ceretherm systems for thermal insulation for external building walls (ETICS). Approximately 2 hours after the application, the foamed polystyrene boards can be smoothed, anchored and then the armoured layer ma..

£14.12

£16.94 inc VAT

Brand: Ceresit

Model and Size: CT87

Delivery Time: In stock, 1-2 days

Ceresit CT87 Adhesive-Filler Mortar is designed to warm up external walls of the buildings by application of external thermal insulation composite system using EPS- or mineral wool façade boards. It is an element of following ETICS from Ceresit: Ceresit Ceretherm Premium or Ceresit Ceretherm Wool Pr..

£27.50

£33.00 inc VAT

Brand: Ceresit

Model and Size: CT87 48 bag

Delivery Time: In stock, 1-2 days

Ceresit CT87 Adhesive-Filler Mortar is designed to warm up external walls of the buildings by application of external thermal insulation composite system using EPS- or mineral wool façade boards. It is an element of following ETICS from Ceresit: Ceresit Ceretherm Premium or Ceresit Ceretherm Wool Pr..

Brand: Ceresit

Model and Size: CT88

Delivery Time: In stock, 1-2 days

Ceresit CT88 Express Application:- Filling gaps between EPS and XPS polystyrene boards- Filling cavities - damage to EPS and XPS boards in the layerinsulating insulation system.

- Adhesive replenishment in the existing insulationProperties:- ideal for filling loses and gaps in the insulation l..

£12.95

£15.54 inc VAT

Brand: Ceresit

Model and Size: 14cm x 28cm - free delivery

Delivery Time: 1 - 2 days

Plastic Trowel used for Insulated Textured Renders..