Ceresit TS62 - Polyurethane gun foam 750ml

- Product Code: U3491

- Stock:In stock, 1-2 days

- Model: TS62

Ceresit TS62 - Polyurethane gun foam 750ml

Ceresit TS 62 PRO is a one-component moisture cure semi-rigid polyurethane foam. It is easily usable and specially made for application with an application gun. While the foam is self-expanding, the post-expansion and curing pressure is minimal, contributing further to convenience and accurate dosage during application. Has excellent adhesion on wood, concrete, stone, metal etc. Yield of the cured foam largely depends on working conditions - temperature, air humidity, available space for expanding, etc. Product does not contain CFC-propellants.

PROPERTIES

- Excellent adhesion on most materials

- High thermal and acoustical insulation

- Very good filling capabilities

- Accurate dosage

STEP BY STEP:

SUBSTRATE PREPARATION

- Ensure substrates are stable, clean and free of substances likely to impair adhesion.

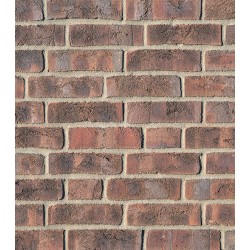

- Moisturize mineral, porous substrates (brickwork, concrete, limestone) with water spray for enhanced adhesion.

- Mask off adjacent areas with foil.

CAN PREPARATION

- Application temperature (environment) of this product is -10°C to +30°C.

- Recommended can temperature is +5 … +30 °C.

- Store can preferably for at least 12 hours in room temperature.

- Remove the plastic cap from the can and either screw the plastic pipe tightly onto the can or screw the can direct and tightly onto the can.

- Shake the can vigorously before use (15 - 20 times).

APPLICATION

- When working with the can always keep the can upside down (valve down).

- Dosage is adjustable by pressing the trigger of the valve. Since the foam is expanding until cured, some free space for expanding should be left.

- Dispense the foam sparingly to avoid excess overflows. Repeat shaking regularly during application.

- Moisturising the surfaces and the foam improves adhesion and cured foam’s cellular structure.

- If there are longer pauses than 5 to 10 minutes during working, the nozzle and valve must be cleaned using PU foam cleaner (e.g CERESIT CLEANER TS100).

- Hardened foam can only be removed mechanically.

LIMITATIONS

Limitations to joint maximal width exist in regard of ambient temperature and humidity levels. In dry conditions (during winter time, in rooms with central heating etc.), in order to get best foam structure and foam properties it is recommendable to fill gaps and joints in several layers by the application of smaller foam strings (up to 3 -4 cm thickness) and slightly moisturizing between every layer. Please use the applicator tested and approved by producer of the can for best working experience.

-250x250.jpeg)