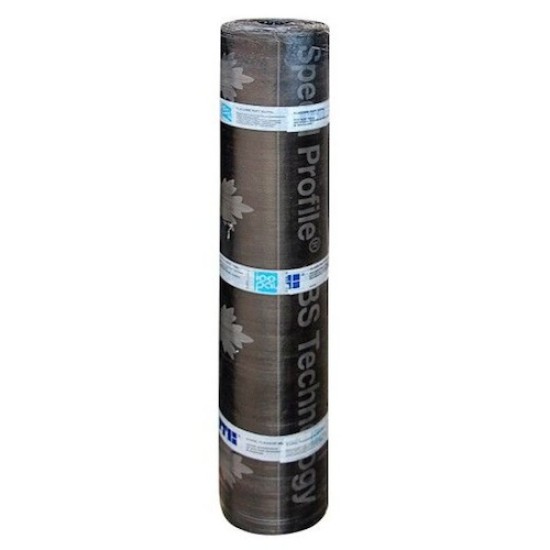

4mm ICOPAL PYE PV250 S4.0 - Torch-On Underlay Roofing felt - 1m x 7.5m roll

New

Get Best Price

4mm ICOPAL PYE PV250 S4.0 - Torch-On Underlay Roofing felt - 1m x 7.5m roll

- Product Code: U3669

- Stock:In stock, 1-2 days

- Model: 1.0m x 7.5m - 7,5m2

- Weight: 43.20kg

- Currently: 20 in stock

4mm ICOPAL PYE PV250 S4.0 - Torch-On Underlay Roofing felt - 1m x 7.5m roll

Length: 7500mm

Width: 1000mm

Thickness: 4mm

Roll coverage: 7.5m2

Weight: 43.2kg

Fire Rating (Reaction to Fire): E

Surface Spread of Flame: Class 1

4mm ICOPAL PYE PV250 S4,0 is a torch-on weldable felt underlay based on polyester non-woven fabric reinforced with glass threads, with a double-sided coating of asphalt mass: SBS modified asphalt with a mineral filler. The top side is covered with fine-grained mineral sprinkles, the bottom side is profiled and protected with plastic foil. The felt is produced according to the patented "QUICK PROFILE" SBS technology.

CHARCTERISTICS

- The roofing felts produced using this technology are weldable felts, modified SBS, which use a unique technology of profiling the underside, weldable side of the felt and a new generation matrix.

- The unique way of shaping the underside of the roofing felt allows for increasing the surface of heat transfer from the burner.

- The special thin anti-adhesive foil burns quickly, thanks to which the heat from the burner through the profile system quickly accumulates on a larger surface of the asphalt than in the case of ordinary roofing felt.

- Can achieve much better parameters in terms of breaking strength and relative extensibility.

- The thickness of the modified asphalt on the outside of the roofing felt has also been increased, which significantly extends the life of the roofing felt and increases its waterproofing and resistance to UV radiation.

- Can be torch applied or mechanically fixed.

- Longer service life.

- Greater durability of the roof covering.

- Complete tightness of the roofing felt coating.

APPLICATION

- Roof waterproofing,

- Roof waterproofing subject to reaction to fire.

INSTALLATION

- The roofing felt should be laid at a temperature not lower than 0°C.

- The rolls must be properly prepared before laying: stored at a temperature of +15°C for at least 24 hours.

- Roofing felt should not be laid on wet roof surface, icing, during precipitation and strong wind.