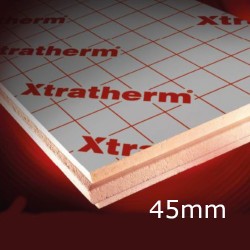

Xtratherm 54.5mm Thin-R Thermal Liner XT/TL-MF - Mech Fix (45mm and 9.5mm)

- Product Code: U1216

- Stock:2 - 3 Days

- Model: 1200x2400 - 2.88m2

- Weight: 24.16kg

Xtratherm 54.5mm Thin-R Thermal Liner XT/TL-MF - Mech Fix (45mm + 9.5mm)

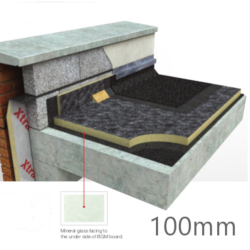

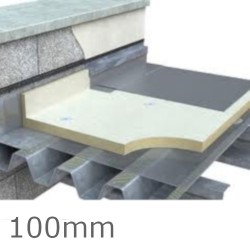

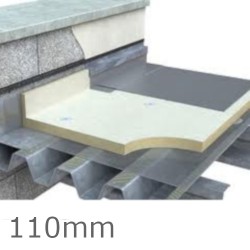

54.5mm Xtratherm Thin-R Thermal Liner XT/TL-MF is a composite insulated panel of 45mm Xtratherm Polyiso (PIR) core with foil faces bonded to 9.5mm tapered edge plasterboard for mechanically fixing to internal walls. XT/TL-MF is designed to provide high levels of thermal insulation and dry lining in one operation for suitable masonry walls, sloped rafters and ceilings in new build and refurbishment situations. XT/TL-MF is only suitable for mechanical fixed applications.

Manufactured to strict EN 13165 standards, the closed cell structure and gas tight facings provides excellent thermal performance and moisture resistance. Xtratherm Thin-R products deliver genuine thermally robust performances and are supported with full third party assurances throughout the range.

Properties

- High Thermal Performance

- Certified Thermal Conductivity as low as 0.022W/mK

- Integral Vapour Control Layer

- 9.5mm tapered edge plasterboard. (You can also order square edge plasterboard.)

- Low Emissivity Foil Facings

- Energy Saving Trust Approved Product

- HCFC/CFC Free, GWP <5

- BRE Green Guide A+ Rated

- Non-deleterious material

- Closed cell structure moisture resistant

- Easy to Install

Uses

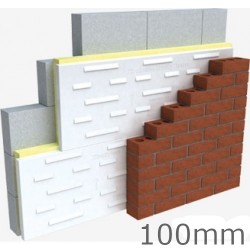

- Masonry walls

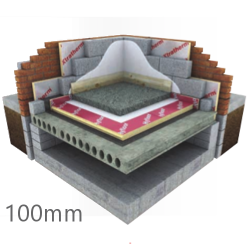

- Sloped rafters

- Ceilings

Installation

- Mechanical Fixing XT/TL-MF Fix a pre-treated timber batten horizontally at ceiling level and another 20mm above the nished oor level.

- Fix vertical battens at max 600mm centres.

- Ensure battens are wide enough to oer 20mm support to all four edges of the plasterboard.

- Pack battens if necessary to level the wall.

- Trim all openings and service penetrations with timber battens.

- Insulation should be cut back to accommodate an adjoining panel at external corners.

- Lift the XT/TL-MF Thermal Liner into position using wedges on the oor.

- Screws should be xed to the timber batten at 150mm centres, at least 12mm in from the board edge. The xings (thermally broken) should penetrate at least 25mm into the batten.

- Installation must be in accordance with good dry lining practice. BS 8212:1988 should be considered, careful setting out and planning is essential.

CERTIFICATION

This product is manufactured in accordance with BS/IS EN 13165:2008

BS EN ISO 9001 Quality Management Systems

BS EN ISO 14001 Environmental Management Systems

BS OHSAS 18001 Health & Safety Management Systems

Energy Savings Trust Recommended Product

-250x250w.png)