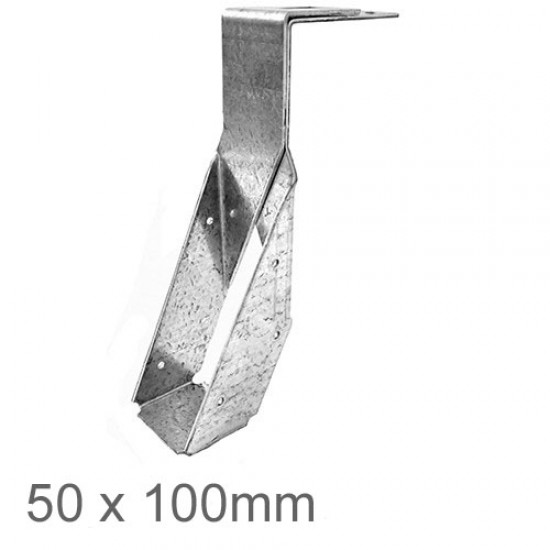

Single Piece Masonry Hanger 50 x 100mm

Get Best Price

Single Piece Masonry Hanger 50 x 100mm

- Product Code: U1546

- Stock:1 - 2 days

- Model: FHM50/100

- Weight: 0.33kg

Single Piece Masonry Hanger 50 x 100mm

50mm x 100mm Single Piece Joist Hanger is designed to provide robust support for timber joists integrated into brick or block walls with a minimum crushing strength of 3.5N/mm. It is equally suitable for a range of timber-to-timber applications, ensuring the masonry flange is securely affixed to the timber or steel beams using appropriate fixings. The straight top flange, along with a lock plate, enables the hanger to be effortlessly transformed into a straddle or hook-over configuration, with no need for specialized equipment. The hanger is rated for a long-term safe working load of 5.4 kN.

FIXING INSTRUCTIONS for 50x100mm Single Piece Masonry Hanger

- The back plate of the hanger should rest flat against the vertical masonry support.

- Masonry flange should have a minimum of 3 courses (675mm masonry) above.

- Both supporting and above masonry should be allowed to cure before any load is applied.

- Joist should be square-cut and sit snugly against the back of the hanger - maximum gap allowed is 6mm.

- Nail the side flanges with 30 x 3.75mm galvanized square twist nails or equivalent. Stainless steel hangers should be nailed using 30 x 3.75mm annular ring shank nails.

- Use HD straps for lateral restraint.

- The masonry flange should always be securely fixed or adequately embedded and should never be placed in dry slots.

- Ensure appropriate fixings are used.

- Always use compatible corrosion-resistant fixings; avoid mixing galvanized fixings with stainless steel products.

- Use mortar of correct strength as per British Standard.

SPECIFICATION

- Galvanized steel to EN 10346 DX51D Z600.

- Tested by CERAM Research Ltd Notification Body No.1289.

- Manufactured to EN 845-1:2013.